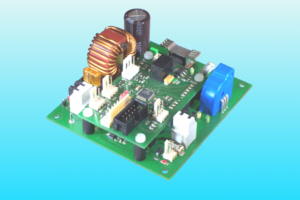

Example: landing flaps drive control unit

We have

developed a landing flaps drive control

unit. The modular design makes the drive

unit suitable for other actuation tasks.

The control unit has several features:

|

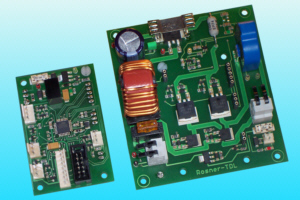

| The modular design with two

boards simplifies the operation in

different power regimes (with only minor

adaptations in the software). The

featured version operates (according to

RTCA DO-160) at 28 VDC and up to 15 A.

The adaptation to positioning tasks and requirements different to the featured landing flap is greatly simplified by the modular design. So especially for compact application with battery supplied actuation systems in research and development (as vehicles, mobile robotics) there are several exchangeable variants with common interface. |